The Sweco Vibratory Shaker is used to separate material based on particle size. This piece of equipment is 48″ in diameter which gives excellent coverage when separating product. IBRL Inventory [...]

The Sweco Vibratory Shaker is used to separate material based on particle size. This piece of equipment is 48″ in diameter which gives excellent coverage when separating product. IBRL Inventory [...]

Glen Mills Model 0101 Jet Mill. Feed rate of 50-1000 grams/hour with a milled PSD of 20 microns. Capable of milling under 10 microns for select products. IBRL Inventory # [...]

The M70 Oil Press is designed to crush oil bearing seeds and nuts to separate oil from biomass. IBRL Inventory # 52-016

The Hammer Mill is used to shred material that will later be used in the machines at IBRL such as Pre-treatment reactor. The hammers inside the machine will break apart [...]

IBRL Inventory # 52-011

The Gravity Table is used to separate materials based on weight and density. It uses a vibrating bed to carry material to the discharge shoots. IBRL Inventory # 52-008

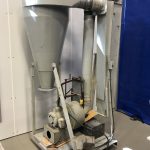

The Aspirator is used to separate the pericarp from the rest of the corn during the dry mill process. The material that needs to be separated is fed at the [...]

The Roller Mill is used to crush the endosperm and flatten the germ during dry mill process. The rollers can be adjusted to break apart many different products. IBRL Inventory [...]

The Sweco Vibratory Shaker is used to separate material based on particle size. This piece of equipment is 36″ diameter which gives excellent coverage when separating product. IBRL Inventory # [...]

The Beall Degerminator is the first piece of machinery used to separate the different parts of corn in the dry mill process. The material passes through the machine and is [...]

The Bauer Mill is the first piece of machinery used to separate the different parts of the corn in the wet mill process. Material is fed through the top and [...]

The Fine Grind Mill is used after the Bauer Mill in the wet mill process. After the germ has been removed, this grinding machine breaks apart the starch material so [...]

The S. Howes Auger is used to move product to an overhead piece of equipment. IBRL Inventory # 52-002

The Variable Speed Auger is used to move product to a piece of equipment. At IBRL, it is normally used to feed material to the Beall Degerminator in the dry [...]