Sridhar Govind, a graduate of the PSM Bioprocessing and Bioenergy program, recently visited IBRL to collaborate on a project. Photo: Kerri Peters.

URBANA, Ill. – Located at the nexus of agricultural crop production and industries that process those grains, the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois provides experiential education to students and helps companies de-risk bioprocessing technologies. The IBRL is among a very select group of institutions that offer an advanced degree in bioprocessing, a critical component in the future of workforce training for the U.S. biomanufacturing industry.

The December 2022 Report to the United States President, “Biomanufacturing to Advance the Bioeconomy,” prepared by the President’s Council of Advisors on Science and Technology, outlines challenges and strategies for biomanufacturing in the U.S. The report identifies building industry capacity and training a qualified workforce as key areas for growth, and it includes the Professional Science Master’s in Bioprocessing and Bioenergy at the U of I in a short list of programs addressing the need for workforce education.

According to the report, the University of Illinois at Urbana-Champaign is one of nine U.S. institutions (four universities and five community colleges) with a specialized degree in this area, and one of only two institutions offering a Master’s degree in bioprocessing.

“The program gave me a fundamental understanding of how the industry functions firsthand. All the classes were focused on the current state of the art in industry, and the IBRL provided me with an opportunity to apply the practices that professors preached,” says Sridhar Govind, who graduated with a PSM in Bioprocessing and Bioenergy in 2018. He now works for San Francisco-based The EVERY Company, which ferments animal-free protein.

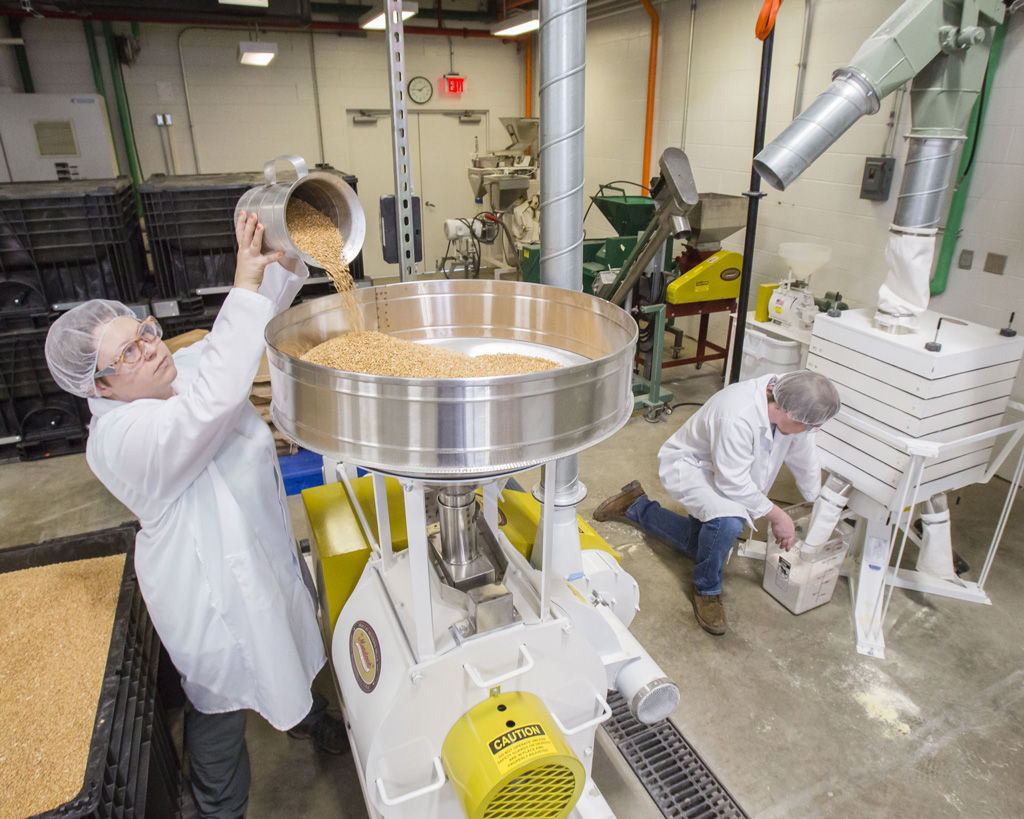

The PSM degree is housed in the Department of Agricultural and Biological Engineering, part of the College of Agricultural, Consumer and Environmental Sciences at U of I. It is a non-thesis master’s program that can be completed in 18 months, typically including three academic semesters and a summer internship. The degree provides hands-on experience working alongside industry clients and partners at IBRL’s state-of-the art facility.

“We have seen exponential growth in the biomanufacturing industry. As more companies are founded, and existing companies shift to incorporate more bio-based processes, they need a trained workforce,” says IBRL Executive Director Vijay Singh.

“The IBRL is providing an educational opportunity to our students that is unmatched in the United States. A combination of technical training, safety training, and interaction with industry representatives makes these students highly employable. There is a huge demand for the students who go through our programs, and we would love to find ways to expand our educational opportunities to prepare more students for highly paid careers.”

The scope of the industry interaction has been enormous for students, Singh notes. Over the past four years, 75 companies have completed projects in IBRL with the majority focused on fermentation-enabled biomanufacturing.

Govind adds, “Currently, there are two significant gaps in the workforce. With a historically low unemployment rate, the demand for bioprocess engineers, bioprocess operators, and scientists far outweighs the supply coming through each year. This in turn causes huge problems for companies developing first-of-a-kind technology to spend significant amounts of time and capital in hiring and training the workforce, rather than focusing on developing the technology. There is a necessity to build a workforce at all levels from the ground up, with a mindset that learners today will be leaders tomorrow.”

Singh explains that as students graduate and join the industry, they share IBRL pilot-scale capabilities with their employers and may even bring collaborations to IBRL to improve or commercialize.

IBRL’s location in the corn belt is ideal for bringing together technical competence with practical application. The raw materials for biomanufacturing are corn sugars, which are readily available in Illinois and surrounding states.

“The foundation for the bio-industrial manufacturing industry already exists in the Midwest,” Singh states. “Companies like ADM, Primient, Tate & Lyle, and Ingredion have been doing agricultural processing here for over a hundred years. Now new efforts to advance bio-manufacturing such as BioMADE, a research program on bio-industrial manufacturing technologies funded by the U.S. Department of Defense, and Liberation Labs, a fermentation-based contract research and manufacturing facility, are identifying the Midwest as the best location for this work.”

The combination of abundant biomass, technical and research expertise, and company collaborations position IBRL and the U of I well for being at the center of a biomanufacturing infrastructure hub, in alignment with another stated goal in the President’s report.

“There is a tremendous amount of momentum in this space, and people are realizing that the Midwest is the place to do it. The University of Illinois is in the perfect position to collaborate and educate to meet this growth,” Singh concludes.

Source: Beth Conerty, bconerty@illinois.edu

News writer: Marianne Stein, 217-244-2313, mfstein@illinois.edu