The DARPA Project Logo

Our current practices of food production use significant amounts of water, land, and other resources, all while generating various agricultural wastes. But food production is so essential that there’s not much we can do about these inherent costs. Or is there?

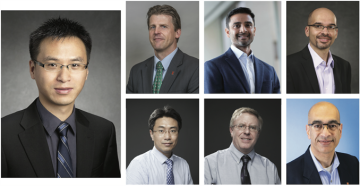

What if we could dramatically reduce the amount of resources needed to make food? What if we could produce food with nothing more than air, water, and electricity? While it sounds futuristic, bioengineering professor Ting Lu and his team of co-PIs–including professors Paul Kenis (chemical and biomolecular engineering), Mohan Sankaran (nuclear, plasma, and radiological engineering), Christopher Rao (chemical and biomolecular engineering), Yong-Su Jin (food science and human nutrition), Keith Cadwallader (food science and human nutrition), and Vijay Singh (agricultural and biological engineering)–believe that this reality might be closer than it seems.

With a steadily increasing global population, a decreasing amount of arable land, and potential production instabilities in the future due to climate change, it is becoming more and more important to identify new ways to produce food. Creating a food source that can be generated anywhere on the planet with minimal resources is the kind of innovation that could make a difference in the future of sustainability.

The team. Starting left and moving clockwise: Ting Lu, Paul Kenis, Mohan Sankaran, Christopher Rao, Vijay Singh, Keith Cadwallader and Yong-Su Jin.

“These types of projects are really exciting because they give us a challenge to think out of the box,” said Lu. “Can we really turn air, water, and electricity into safe, palatable, and nutritious food? It’s a very ambitious goal, but one that we are looking forward to meeting.”

After successfully applying for and receiving a four-year, $10.4 million research grant from the U.S. government agency Defense Advanced Research Projects Agency (DARPA), Lu and his fellow co-PIs are ready to get to work on their three-ingredient food.

“The process requires several steps that are each in their own right complex, and then all the steps must be integrated to work together,” said nuclear, plasma and radiological engineering professor Mohan Sankaran, a fellow co-PI on the project. “Some of those steps are to ‘fix’ the N2 and CO2 in air to compounds such as ammonia and acetate. Next, these compounds are fed to microbes to produce biomass containing the proteins and carbohydrates that make up food.”

Currently, Lu envisions this food as more of a supplement than a full meal, with plans to structure this new source of nutrients into three different forms: a shake, a gel, and a dried jerky. Lu has a goal of producing 100 grams of food next year, and a broader goal of one day seeing production plants that create the food on a larger scale.

Not only is this proposed technology faster in food production and better for the environment than our current methods, but it’s highly portable. If this method takes off, food could be possibly produced in the South Pole as easily in the Midwest. Inhabitants of remote islands, mountains, rainforests and beyond could all produce their own food, regardless of land or other natural resources.

But even a food source that’s a scientific marvel has to taste good. “Flavor quality is the main determinant of food acceptance by the consumer,” said co-PI and food science and nutrition professor Keith Cadwallader. “In our project we are taking a practical approach by designing systems that create a variety of generic flavors that mimic certain classes or types of popular flavors, such as “sweet aromatic”, “fruity-berry” and “savory-meaty” flavors.”

It’s just one more element of this three-ingredient food to look forward to: it will come in a wide range of flavors, from sweet to savory, no matter what form it takes.“Our goal is not to make a food with a single flavor but to make foods that can be easily customized for consumer preferences, like when we choose vanilla, strawberry, or chocolate flavors in ice cream shops,” said fellow project co-PI and food science and nutrition professor Yong-Su Jin.

Scale-up of this project and end-to-end integration will be conducted by agricultural and biological engineering professor Vijay Singh, another co-PI on this project. This work is being conducted in his lab and at the Integrated Bioprocessing Research laboratory (IBRL), a translational research facility at the University of Illinois.

“At IBRL, we have most of the bioprocess equipment required to conduct full demonstration of this exciting project creating food from air, water and electricity,” said professor Singh, who also serves as Executive Director of IBRL.

Clearly a project of this scale requires expertise on many levels. Lu was quick to point out that their project is a true team effort that benefits tremendously from the breadth of research and collaborative culture of the University.

“I am so grateful to be a member of this interdisciplinary research team,” said Jin. “Our UIUC team is the only one comprising all team members from a single research institution among the DARPA awardees.”

It’s rare to have the opportunity to work on a project that incorporates so many disciplines and could one day have an effect on such a basic element of our everyday lives, and Lu is eager to see the project through.

“If successful, our project will have a potentially transformative impact,” Lu said. “We’re grateful to DARPA for this opportunity and excited to be able to work on something that we feel special.”

By: Bethan Owen